Biogas

Biogas is produced by methane fermentation of biomass. It is a flammable gas.

The active factor in the fermentation process are anaerobic microorganisms, whose metabolism involves the decomposition of organic matter to simple substances.

Biogas usually includes:

| Methane | CH4 | 45 – 85 % |

| Carbon dioxide | CO2 | 10 – 55 % |

| Nitrogen | N2 | 0 – 10 % |

| Oxygen | O2 | 0 – 5 % |

Biogas produced in sewage treatment plants, landfills, in agriculture and as a by-product in biomass processing is an excellent fuel for production of cheap electricity and heat for your companies needs and for sale. However, before use, biogas must be cleaned of hydrogen sulfide, dust and siloxanes.

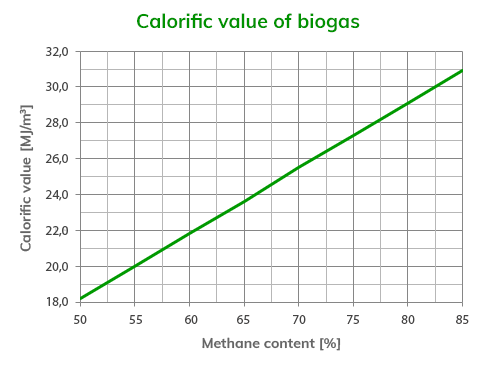

Below is a graph of the calorific value of biogas calculated based on the ZN-G-4002 standard.

BIOGAS IMPURITIES:

Purifying biogas from the above pollutants is key to ensuring failure-free operation of engines, gas turbines and boilers. Hydrogen sulfide in combustion processes produces a highly acidic environment, which favors the erosion of metallic alloys and the decomposition of lubricating oils. Crystalline silica, which forms during the combustion of siloxanes, acts as an abrasive material on sliding surfaces in engines. It may also stick to turbine blades or surface of boilers, which results in many failures. However, excessive moisture in biogas enhances the above processes, facilitating chemical erosion of devices and fittings. Thus biogas purification is extremely important to ensure failure-free operation of devices.