Methods of DESULPHURIZATION

Comparison of various biogas desulfurization methods available on the market

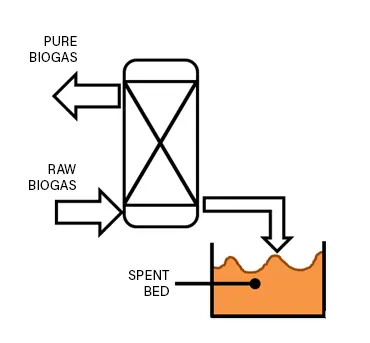

1. Fixed bed biogas desulfurization method

| DIAGRAM | CHARACTERISTICS | WASTE | WASTE FEATURE |

|---|---|---|---|

|

Biogas desulfurization using a fixed bed with a cleaning mass based on bog ore - non-regeneration version. The regeneration version needs building a regeneration installation (or contract out such a service). | Solid waste (difficult to load and transport). |

Large amount: up to a hundred times greater than H2S in gas. Compounds soluble in water (potential water pollution). Dangerous, often pose a risk of spontaneous combustion. |

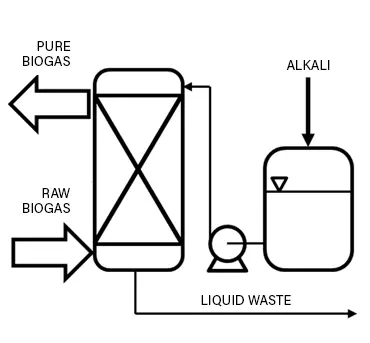

2.1. Wet alkaline methods (chemical biogas desulfurization)

| DIAGRAM | CHARACTERISTICS | WASTE | WASTE FEATURE |

|---|---|---|---|

|

Absorption of hydrogen sulfide in an alkaline solution. The solution is not regenerated. | Liquid solution containing absorbed hydrogen sulfide H2S. |

An amount several times higher than the H2S content in the gas, but lower than when using fixed bed biogas desulfurization method. Water-soluble waste - potential contamination of groundwater. |

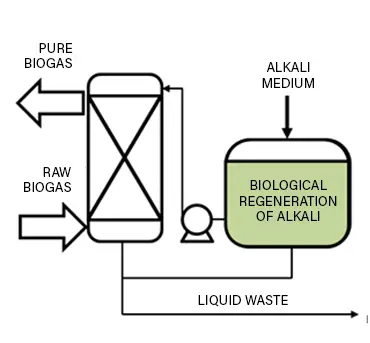

2.2. Wet biological methods (biological biogas desulfurization)

| DIAGRAM | CHARACTERISTICS | WASTE | WASTE FEATURE |

|---|---|---|---|

|

Absorption of hydrogen sulfide in an alkaline solution. The alkaline solution is biologically regenerated. The method is sensitive to changes in H2S concentration. | Liquid solution containing sulfur compounds, sulfur and partially absorbed hydrogen sulfide H2S. | Desulfurization of biogas using this method is an improvement over the methods 1. and 2.1. but does not always guarantee the expected efficiency of the process, especially when biogas purification takes place in variable technological parameters. |

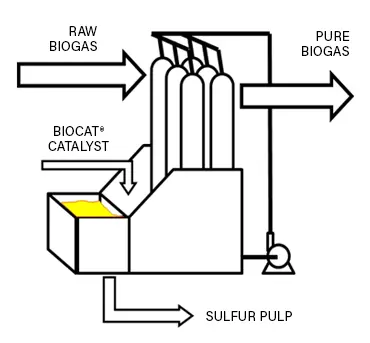

3. BIOSULFEX® method (innovative biogas desulfurization)

| DIAGRAM | CHARACTERISTICS | WASTE | WASTE FEATURE |

|---|---|---|---|

|

Biogas desulfurization using an environmentally friendly wet catalytic method that converts all H2S into non-reactive elemental sulfur. No waste. Resistant to changes in H2S concentration. It can be supplemented with a heterogeneous moisture removal module, which makes biogas purification comprehensive. |

Sulfur pulp -

the amount of pulp is equal to the amount of H2S in the gas (the smallest possible). |

Non-reactive sulfur pulp paste like consistency (in large quantities, a potentially valuable chemical or agricultural raw material). Non-reactive, non-flammable. |